I had a go at converting a 4 stroke glow engine to run on petrol so I thought I’d write about my experience here. The first and obvious question is: “why do it at all?” Pete actually asked me this when I was trying to start the engine at the field.

To be honest I was more interested in the technical challenge than actually thinking about the benefits.

Here’s what I’ve read, for and against, on the subject:

For

1) Petrol is about 1/3rd the price of glow fuel.

2) The engine actually consumes about 1/2 as much petrol per minute as glow fuel. Meaning that the fuel is in effect about 1/6th the price.

3) A low and reliable tick over can be achieved.

4) It doesn’t splurge a load of oil residue all over your plane.

5) The added weight of the CDI + battery can be offset by using a much smaller fuel tank e.g. a 120 glow engine needs about an 18oz tank. With petrol you can go down to an 8-10oz tank – more than covering the CDI+batt weight.

Against

1) Petrol stinks

2) The conversion takes time and money (about £60).

3) The CDI unit+leads weighs 104g, and it has the power consumption of about 4-5 std. servos when they are operated in flight. Most people fit a separate battery so that’s another 100g.

4) The converted motor will make less power.

5) It adds complexity.

6) If you already run glow engines too, then you need separate fuel containers and pumps etc.

7) You need to pre-mix the fuel and oil yourself.

If you’re willing to put up with the smell, and the complication fuss (e.g. mixing your fuel and oil), then the main drawback is the lower power output. The main plus is the economics, especially for 120 and above engines.

The lower power output is a similar issue to the difference between two and four stroke glow engines e.g. A .46 two stroke is roughly equivalent (power-wise) to a .70 four stroke. The .70 weighs more so the plane’s aerodynamic performance drops slightly.

The difference between petrol verses glow power is not quite so large. From what I’ve read, a petrol engine will be 80% as powerful as the same size glow engine.

Given this, a petrol setup favours larger planes (say 120 and above) where the fuel savings are significant. It’s worth noting that there seems to be very few petrol four strokes out there. There are a couple of large Chinese 38cc motors at a good price and the almost fantastically expensive Saito petrol engines.

My Conversion Experience

The motor I was planning to convert is an ASP 120 four stroke. It was well used but still felt smooth and had good compression.

I started by calling Just engines who sold all the necessary bits. My main concern was finding out whether the standard carburettor could be used. I was unsure as to whether a pumped carb might be required (as fitted to all the petrol engines I’ve seen so far). I was also worried that setting the needle valve might be difficult as mentioned in some posts I’ve read on the subject.

After asking a few questions about my motor, the man at Just Engines said that he expected the standard carb to work fine and advised at least trying it before buying a pumped carb and then having to make/buy an adapter to allow it to be fitted to my engine.

The parts needing to be purchased for the conversion were:

1) An ignition (CDI) system for glow plug motor (has a smaller plug cap)

2) A spark plug designed to fit the glow plug thread size.

3) A pair of shims to lower the engine compression. Not absolutely essential but recommended.

The only tricky part of the conversion is mounting the sensor that signals the CDI when to fire. The sensor supplied has a plastic housing with elongated mounting holes, which allow its position to be adjusted by a few degrees.

The picture shows this setup screwed to a ring that is on the outside of the engine’s front bearing housing.

The picture shows this setup screwed to a ring that is on the outside of the engine’s front bearing housing.

I guess that because of the huge variation in crankcase design/sizes, a mounting ring isn’t supplied or available anywhere as far as I could tell. I’m not sure how this is secured to the engine either.

One quick method suggested in the instructions was to use a hose clamp (or jubilee clip), which I guess would work OK and doesn’t require special tools.

As I have machine tools, I decided to have a go at making my own clamping ring with a single screw to loosen/tighten for adjustment.

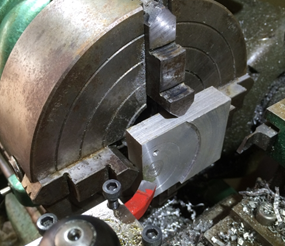

I started with a bit of scrap aluminium in my lathe chuck, which I cleaned up so I had a flat face to work with.

I started with a bit of scrap aluminium in my lathe chuck, which I cleaned up so I had a flat face to work with.

I then prepared to machine out a 32mm hole, which was the size needed to fit over the front bearing housing.

I then prepared to machine out a 32mm hole, which was the size needed to fit over the front bearing housing.

I turned a lot of solid aluminium into little curly bits of swarf to make that hole.

I turned a lot of solid aluminium into little curly bits of swarf to make that hole.

By the way, that is a DeWalt Extreme drill bit and they are just brilliant at making holes in metal. No pilot hole required for a 13mm bit, just plunge it straight in.

After drilling to 13mm, I used some larger bits to take it gradually out to 20mm and then a boring tool to open out to 32mm. It takes a while.

With the 32mm hole done, I then sketched the clamp shape onto the metal (just a rough free-hand sketch) and cut away most of what I didn’t need with a saw and file. This is way quicker than machining it.

I cut the split with a slitting saw on my mill but this could have been done with a standard hack saw. The chunk of metal left on to house the sensor was drilled to 7mm as close to the 32mm hole as possible (this should have been done before the 32mm hole was bored – oops! bad planning). I actually got it close enough to break into the 32mm hole, which was what I wanted.

The outside was then machined on my mill using a rotary table. Again this was unnecessary and could have just been filed to a reasonable finish. Finally, I drilled and tapped the hole to clamp the ring and another hole to fit the grub screw that secures the sensor.

The final result looks like this:

OK I’ve used tools that not everyone has but bear in mind that apart from the 32mm hole, everything else could have been done with a hand held power drill, a hack saw and a file.

OK I’ve used tools that not everyone has but bear in mind that apart from the 32mm hole, everything else could have been done with a hand held power drill, a hack saw and a file.

A nut and bolt could be used for the clamp and the sensor could be just glued in (the sensor is slightly tapered so once pushed in it gets to be a real tight fit in the 7mm hole).

All this machining took ages on my lathe and mill (I’m no engineer) and at times I wish I’d just used a hose clamp!

All this machining took ages on my lathe and mill (I’m no engineer) and at times I wish I’d just used a hose clamp!

Still, now it’s finished I’m glad I did it. Here it is, trial fitted to the motor.

The next job was to fit the magnet to the engine’s prop driver. The magnet is a 4mm cylindrical neodymium thing that will ferociously latch on to any nearby ironmongery. A 3.9mm drill bit is supplied with the kit. As I had a fully adjustable sensor position, I only had to concern myself with how far forward (i.e. towards the prop – away from the front bearing) the magnet needed to be.

As it happened, I needed to drill right at the point where there is a small step change in the prop driver’s diameter. This is easily dealt with however using a centre drill. This type of drill bit is very useful anyway if you are drilling into a circular item. An ordinary drill bit will have a tendency to wander off to one side. The centre drill stays true because it is very short and has a relatively large diameter shank except for the last few mm leading to the tip.

If you have access to a pillar drill and a vice

Getting the drill located centrally on a circular item is easily done with something like a short steel rule. Just lightly pinch the rule with the drill bit, if you’re bang on centre, the rule will be parallel to the vice jaws. If you’re a bit off to the right (as in the photo), then it will be angled down towards the vice jaws on that side.

If you don’t have access to a pillar drill and a vice

If you don’t have access to a pillar drill and a vice

I’m pretty sure nothing is super critical here and you can just do it by eye. If the magnet passes close to the sensor, it will fire the ignition. Having the magnet at a slight angle isn’t going to make much difference as far as I can see.

Here’s the pilot hole drilled ready for the 3.9mm bit to follow.

Here’s the pilot hole drilled ready for the 3.9mm bit to follow.

I think the magnet was a bit over 4mm long so I drilled the 3.9mm hole to a depth of 5mm.

Again, not critical just make sure it’s deeper than the magnet. There’s loads of metal to play with.

After drilling, the next step is to press the magnet into the hole. Actually, before that happens, you must ensure that the magnet is the right way round. To do this, fit the spark plug into the cap and plug the battery into the CDI. Then holding the magnet in your fingers, just move it over the sensor. You will only get a spark when the correct end of the magnet is facing the sensor. Mark this end with a felt tip or something, then you’re good to press it in.

Above, you can see I’m pressing the magnet in with my vice. I’m protecting the prop driver by using a soft jaw on that side of the vice. It required a considerable (and alarming) amount of force to press the magnet in but even a small vice would do the job.

Above, you can see I’m pressing the magnet in with my vice. I’m protecting the prop driver by using a soft jaw on that side of the vice. It required a considerable (and alarming) amount of force to press the magnet in but even a small vice would do the job.

[Note: The rare-earth metals that these magnets are made of are very brittle. It cannot be hammered in because it will just shatter.]

[Note: The rare-earth metals that these magnets are made of are very brittle. It cannot be hammered in because it will just shatter.]